App Description Page

MRP Subcontracting

This module helps generating PO for subcontracting services, it's allows user to manage stock and bills for subcontracting process. If work-order contains subcontracting product as raw material, 'Subcontracting Order' button will be visible in that work-order. It will create delivery orders and purchase order from manufacturing order.

Key Features

- Configure subcontracting on the BOM of component product of the finished product.

- Create subcontract orders and related delivery orders and PO from the work-order.

- On cancelling the MO, all the subcontracting orders are cancelled automatically.

- Manage stock for subcontract process.

- Show warning in case of raw material out of stock.

Configuration

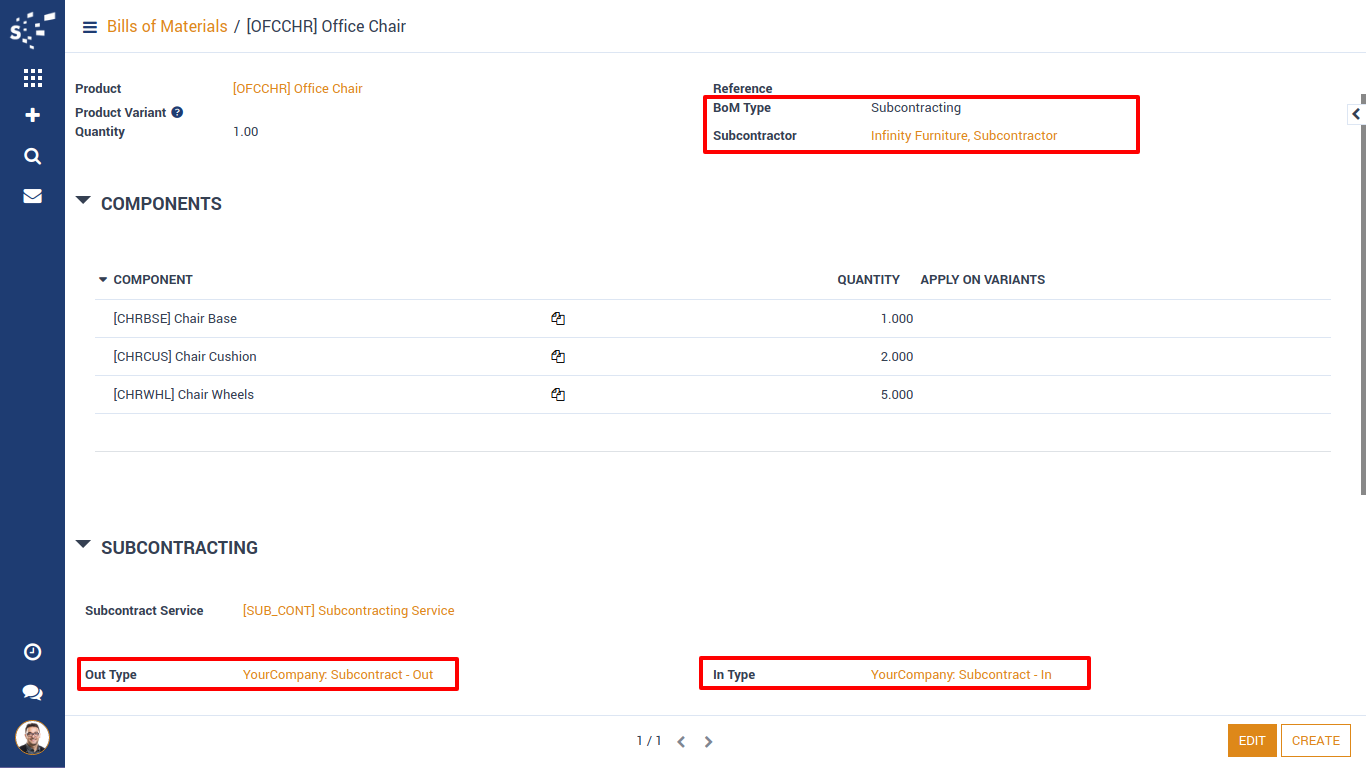

While creating "Bills of Materials" if product is used as a raw material and product are given away on subcontracts for production, then Select BOM Type 'Subcontracting' and configure subcontractor details.

'Out Type' and 'In Type' are required to create BOM of subcontract type. They are picking types used to create in and out delivery orders. Configure locations for both in and out pickings.

Create Bills Of Materials

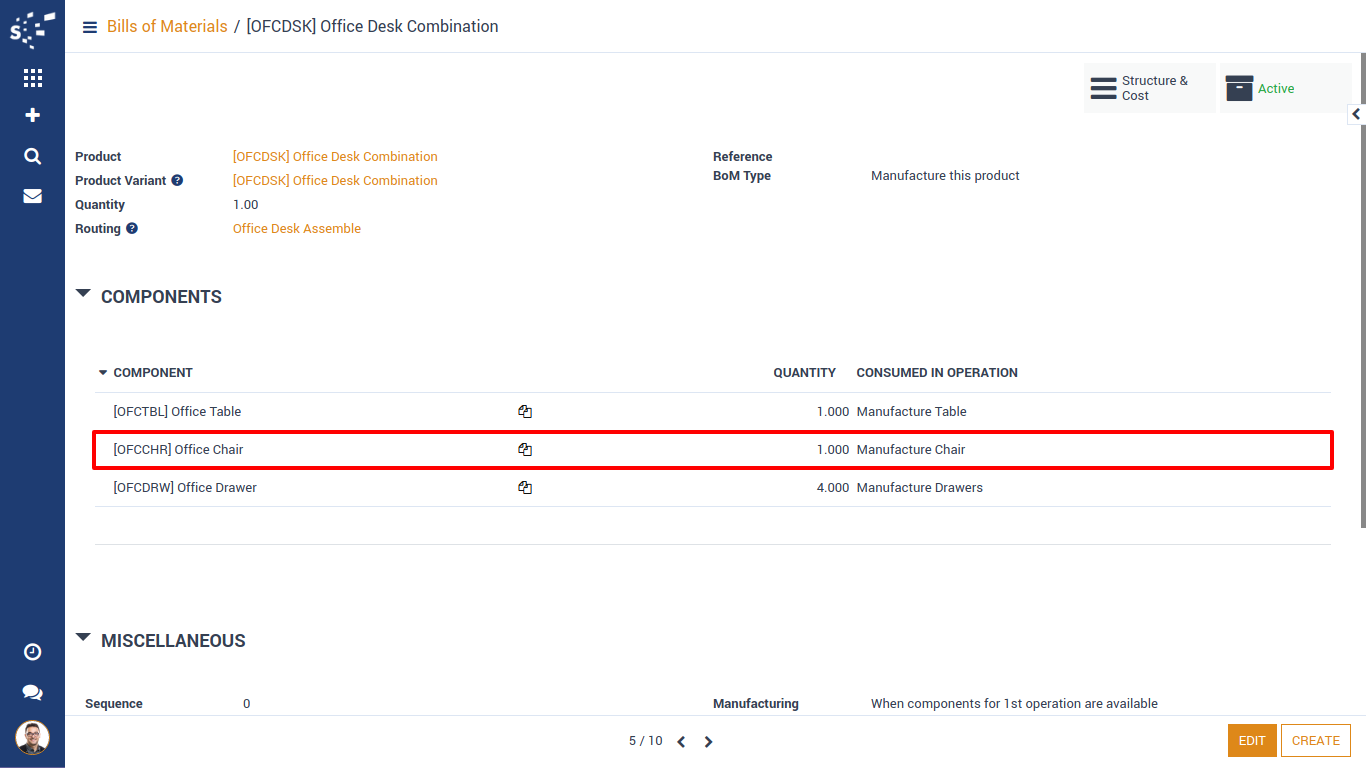

Create "Bills of Materials", its contains subcontracting products.

Create Manufacturing Order

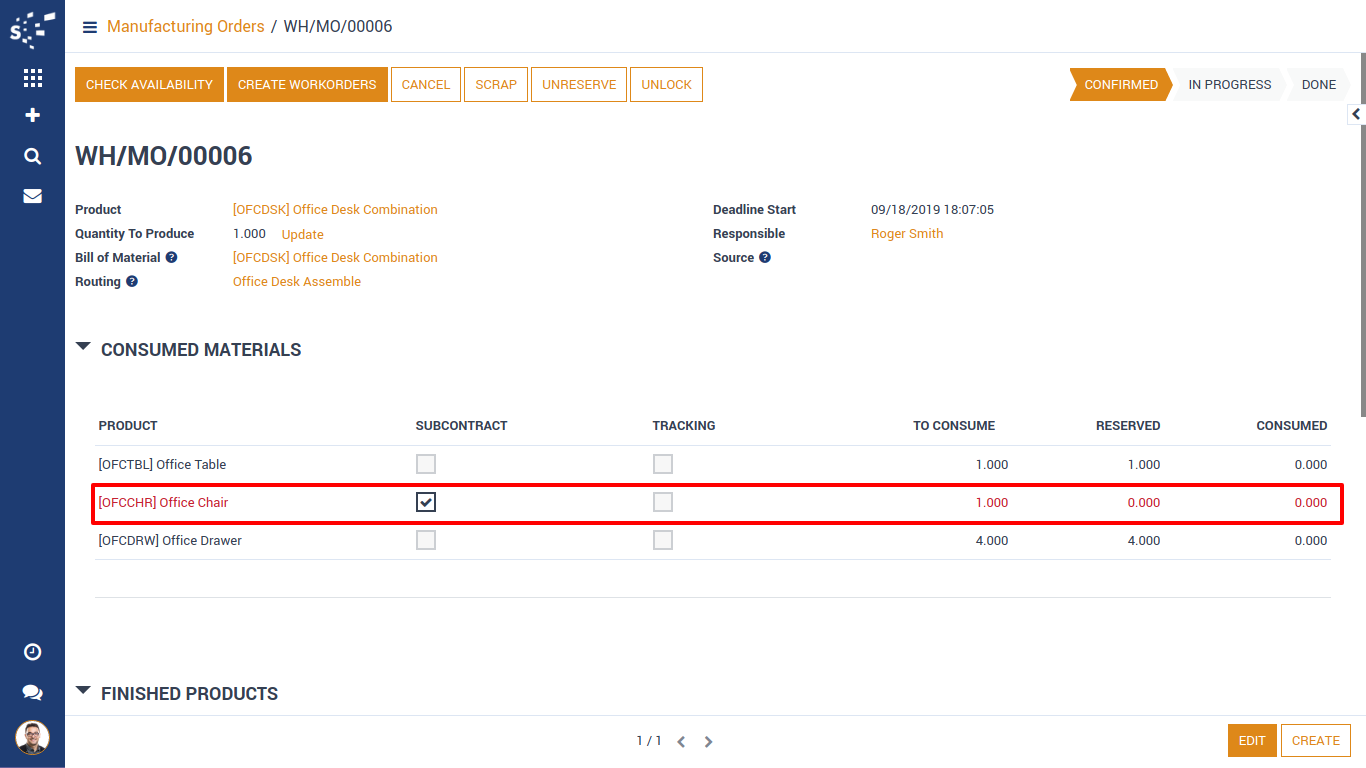

Create Manufacturing Order for Bills of Materials, its contains subcontracting products.

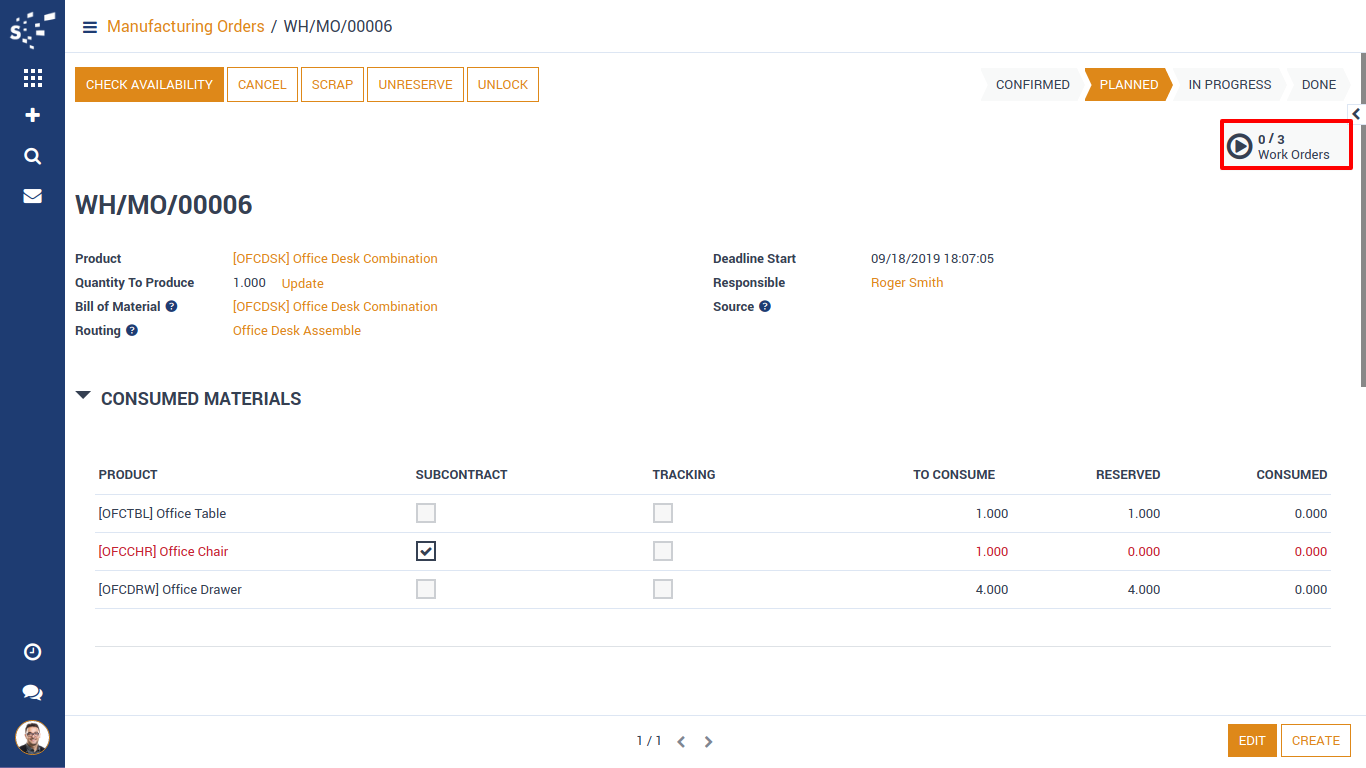

Create Work-orders

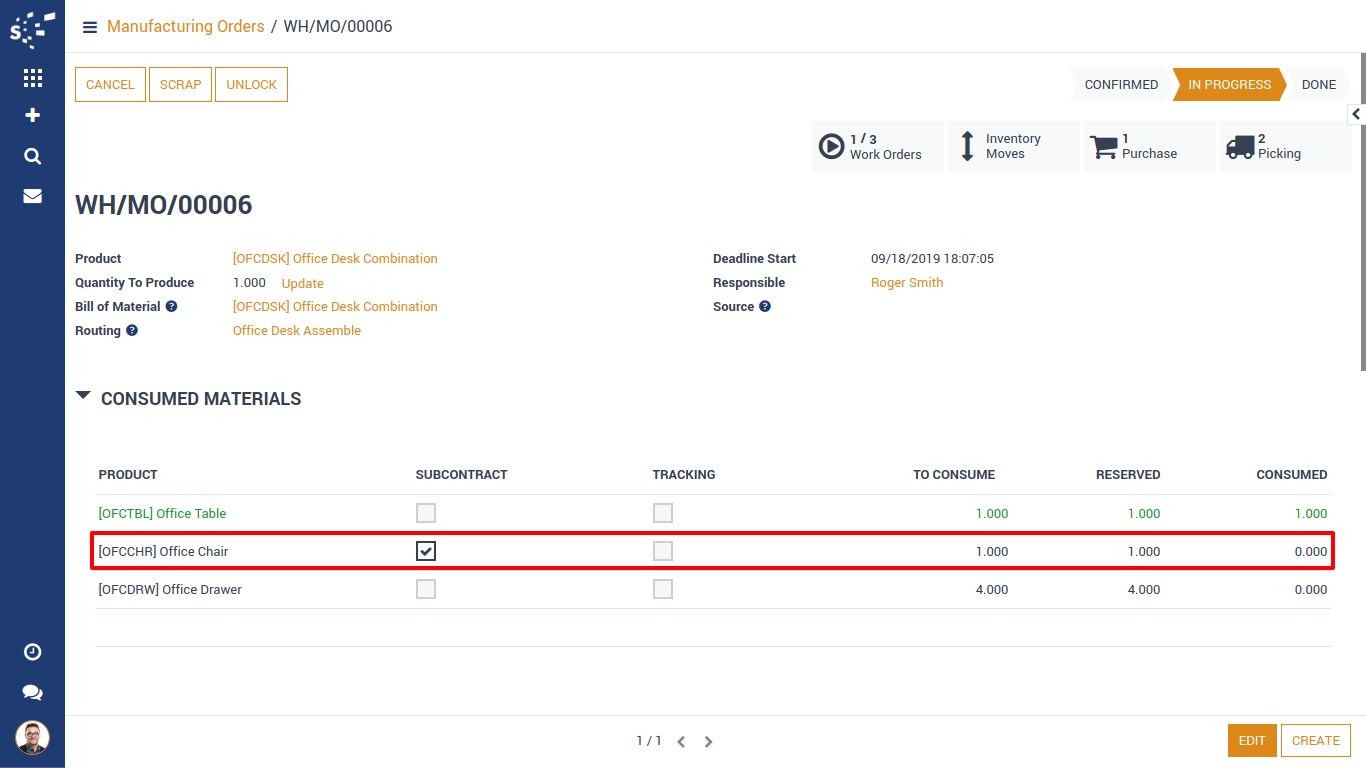

Create Work-orders for manufacturing order by clicking on 'Create Work-orders' Button. As we can see here 3 work-orders are created as per our configurations and subcontracting raw material stock is not available in warehouse. Other raw materials have stock in warehouse and they are reserved.

Process Work Orders

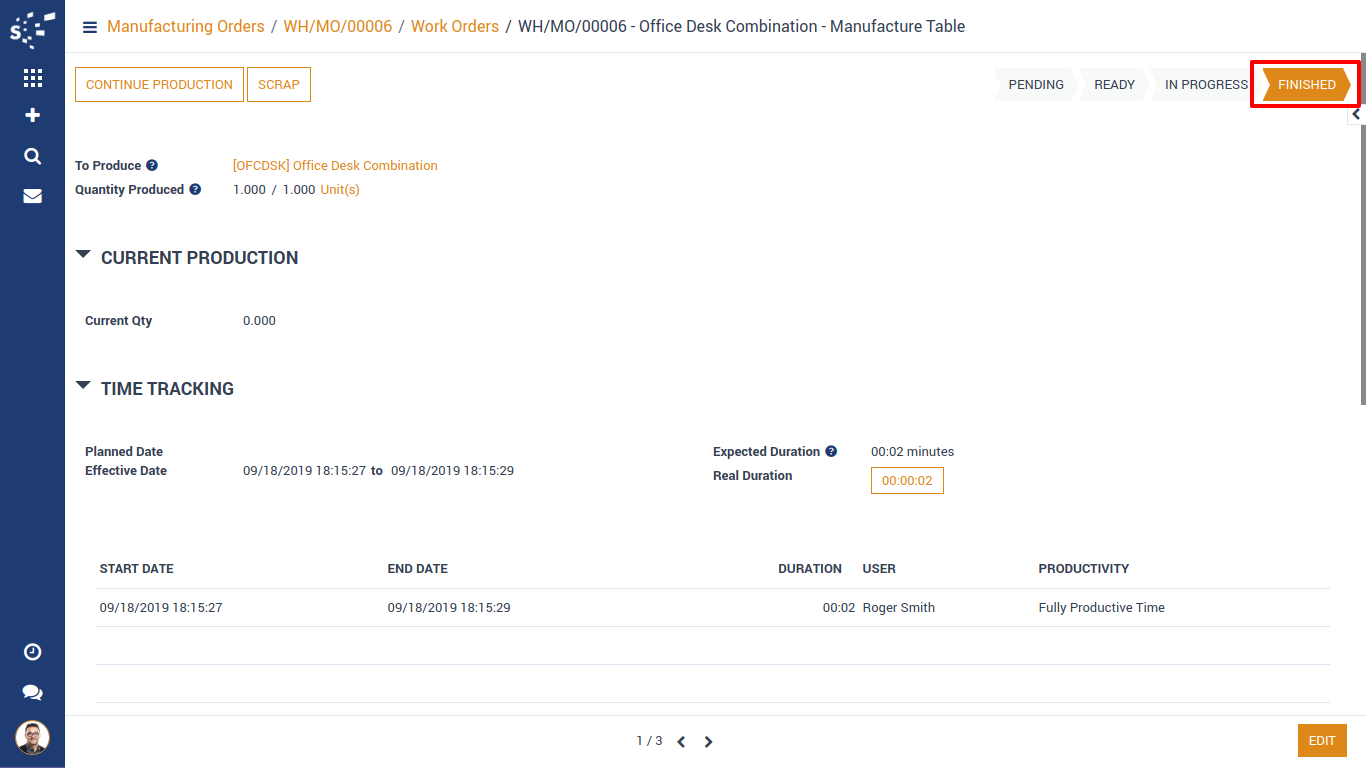

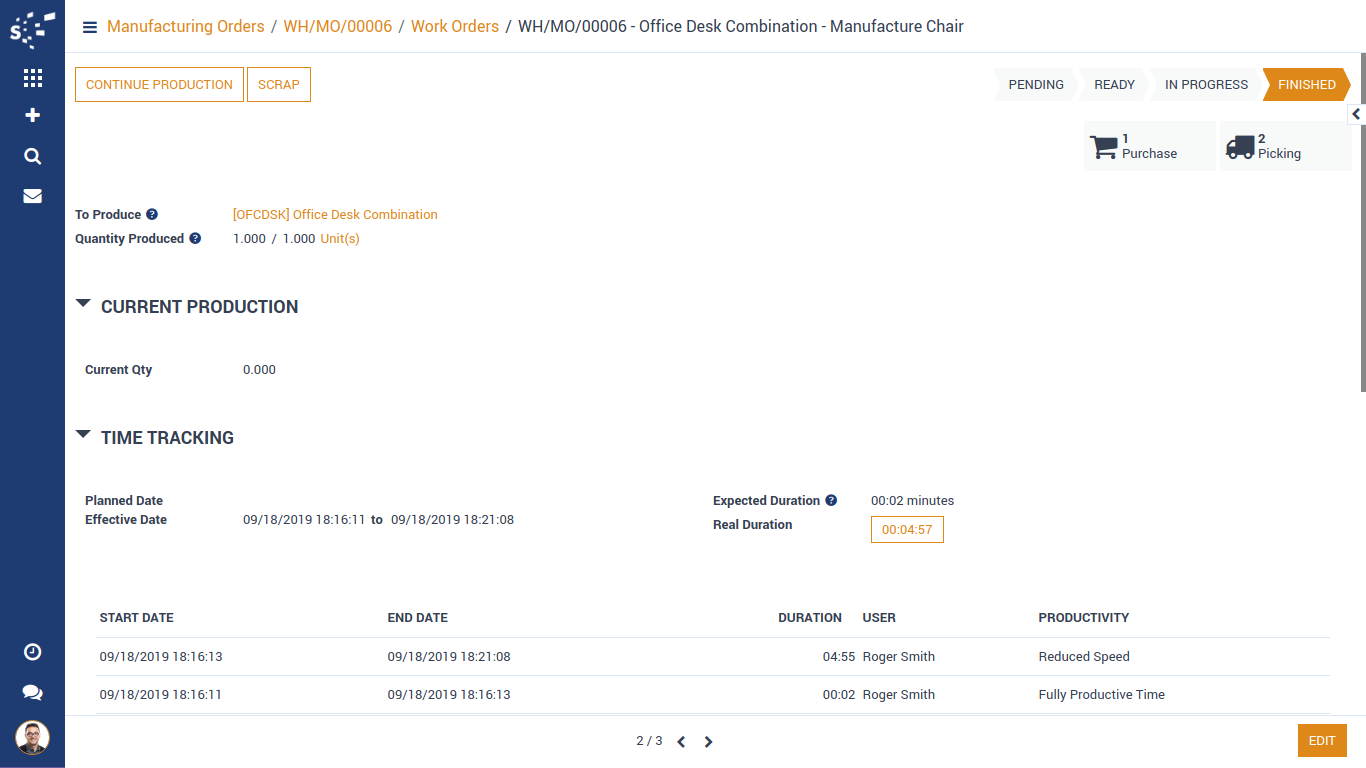

First work-order will be finished successfully because we have raw material in stock.

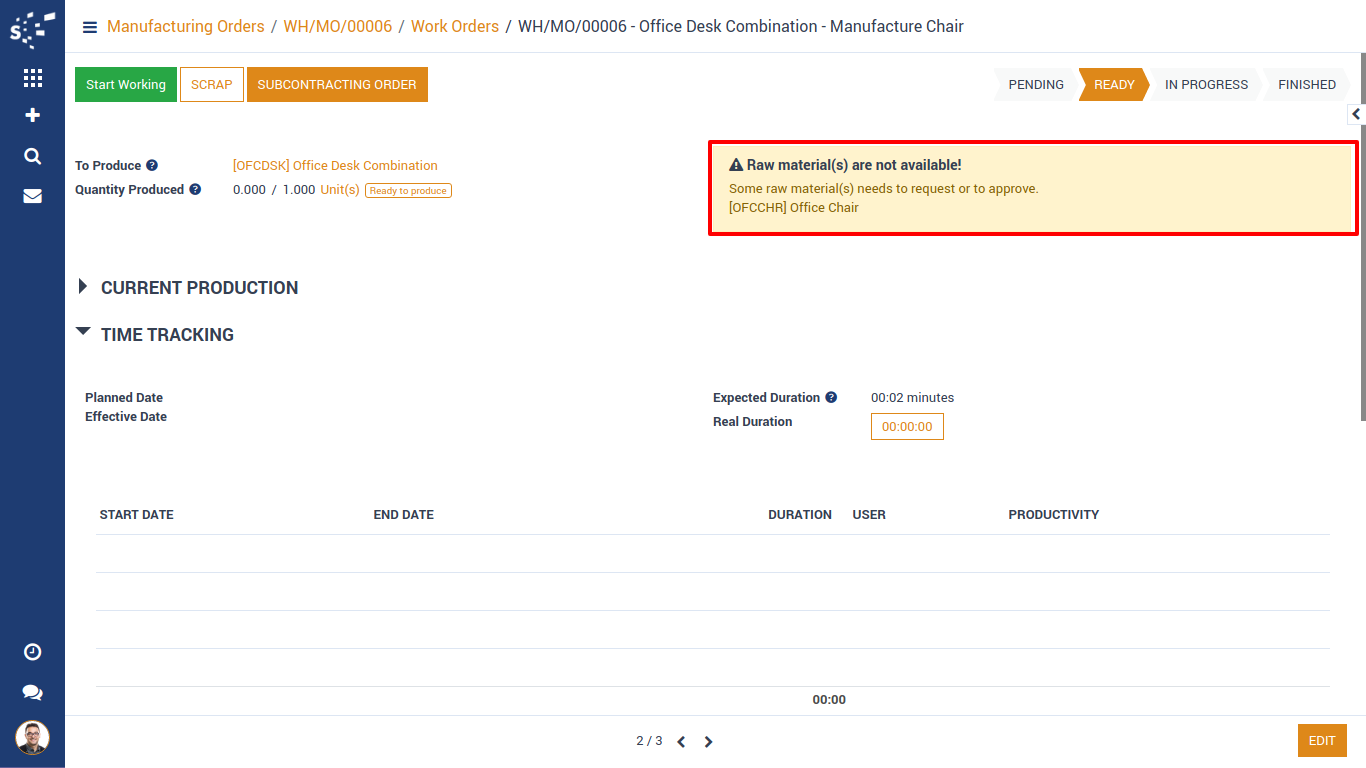

Second work-order contains subcontracting raw material. Which is not available in stock. So here system will give warning of 'Raw Material(s) are not available!'.

If you have already processed subcontracts and still getting this warning. Go back to manufacturing order and click on 'Check Availability' button.

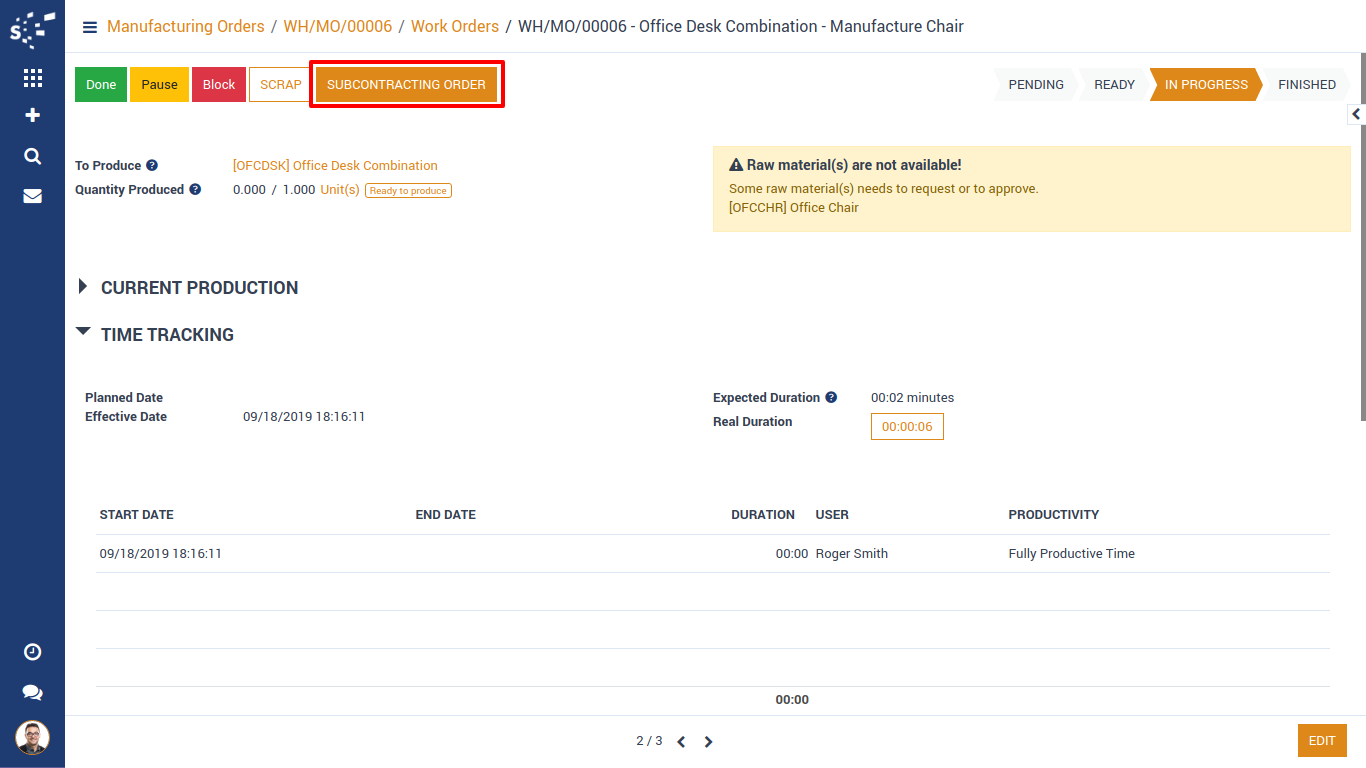

Click on 'Subcontracting Order' button and it will create 2 pickings :

1. Out picking for subcontracting product raw materials.

2. In picking for subcontracting product.

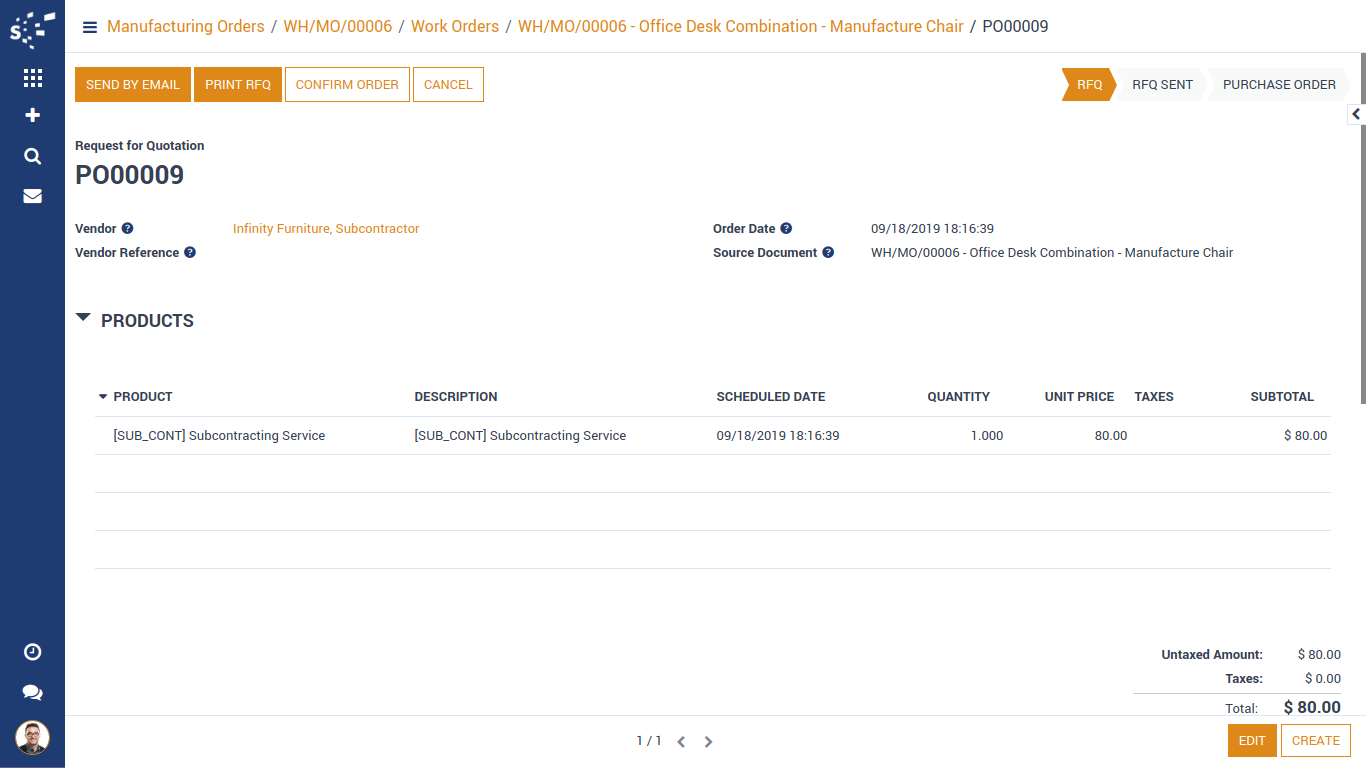

It will also create a purchase order of subcontracting charges (Service).

We can start work-order even if raw material is out of stock. But we can not finish it. It's up-to user if want to include subcontract time in work-order or not.

Process Subcontract

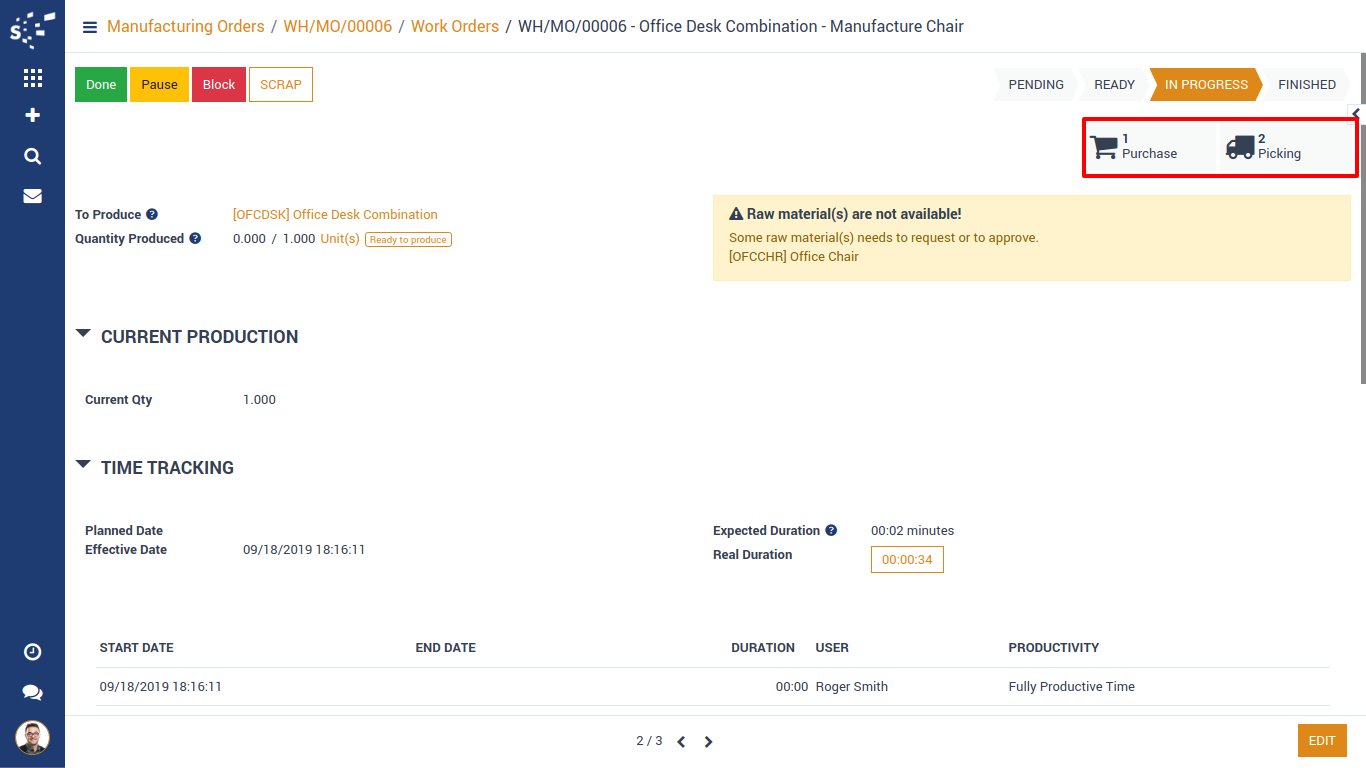

Click on 'Subcontracting Order' button. It will create 2 pickings and 1 Purchase order and link with related work-order.

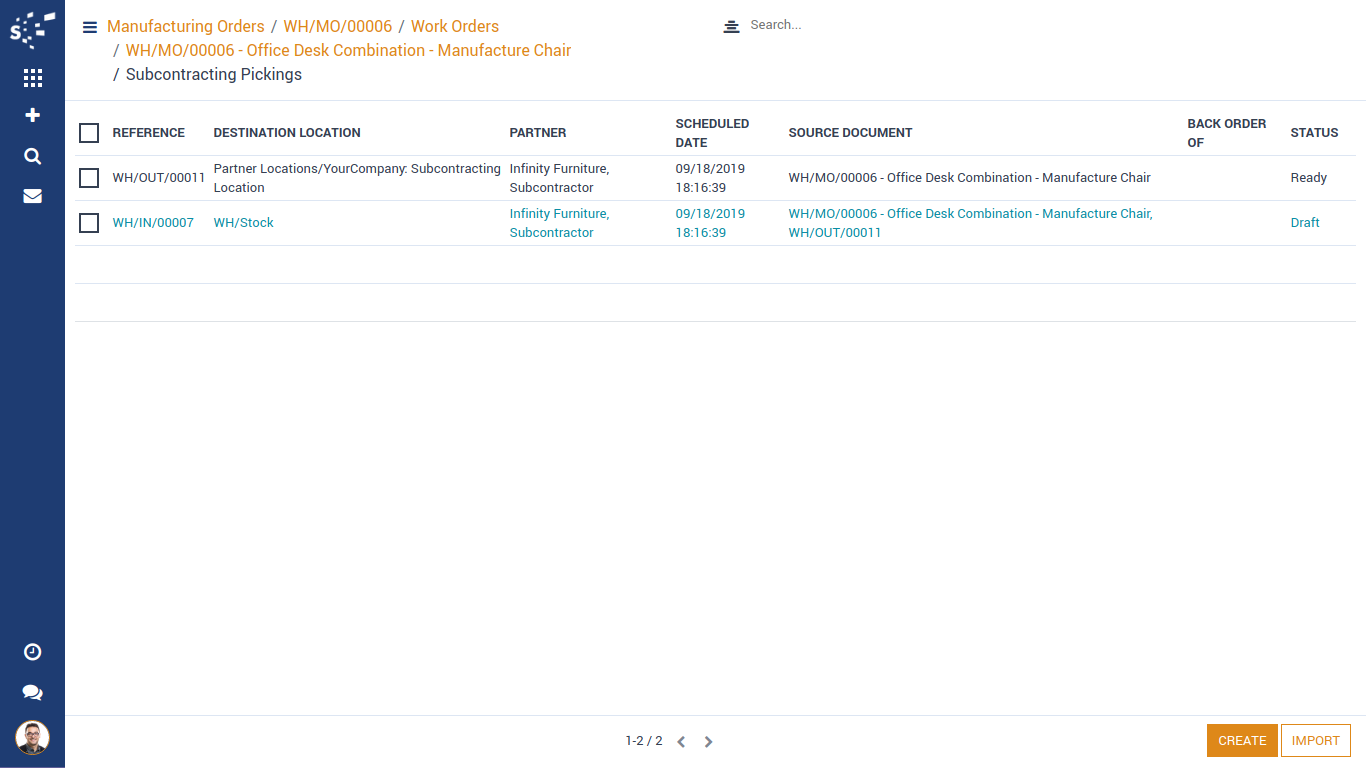

These Are 2 pickings created. WH/OUT/00011 is outgoing picking of subcontract raw materials and WH/IN/00007 is incoming picking for subcontracting product.

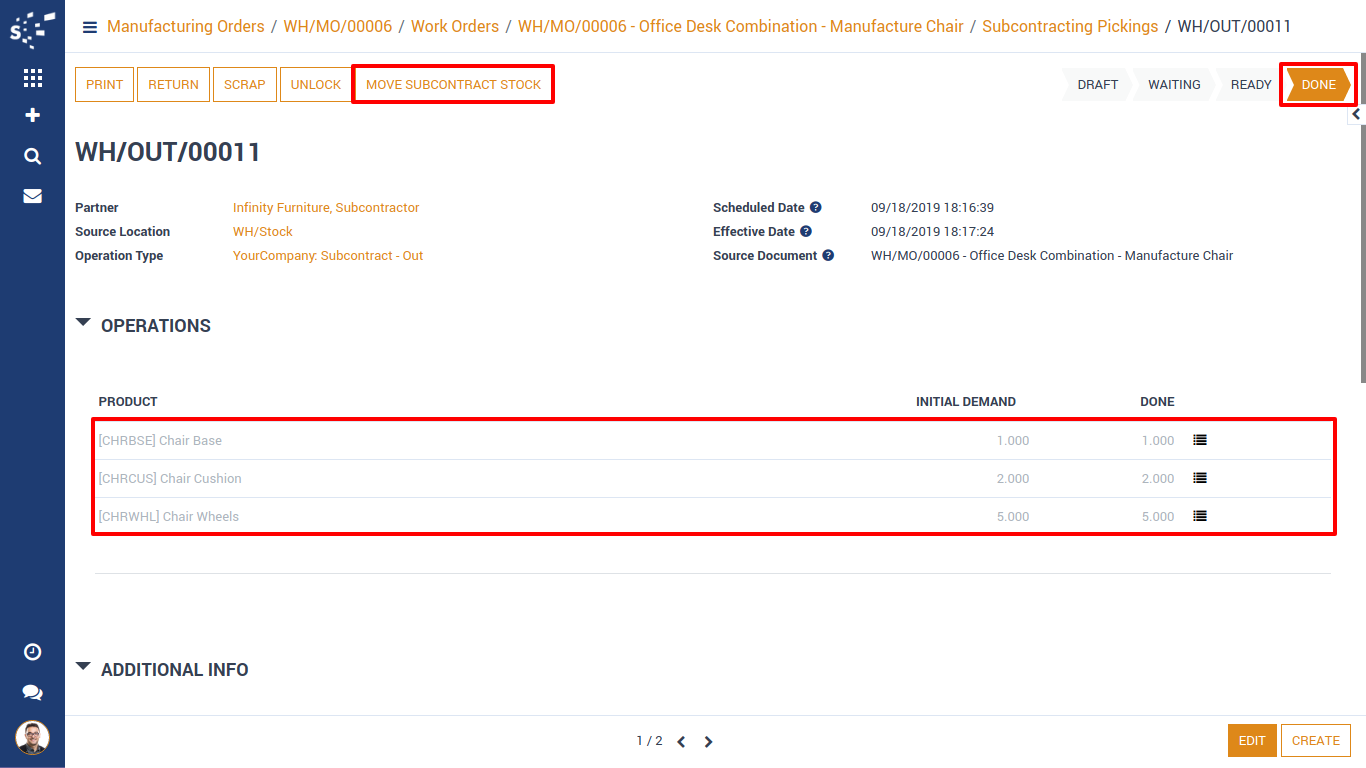

When outgoing picking is transferred, user can see a button 'Move Subcontract Stock'. Right now subcontract raw material stock is in subcontract location. when subcontract process is done, user will click on this button and move subcontract raw material stock to subcontract done location.

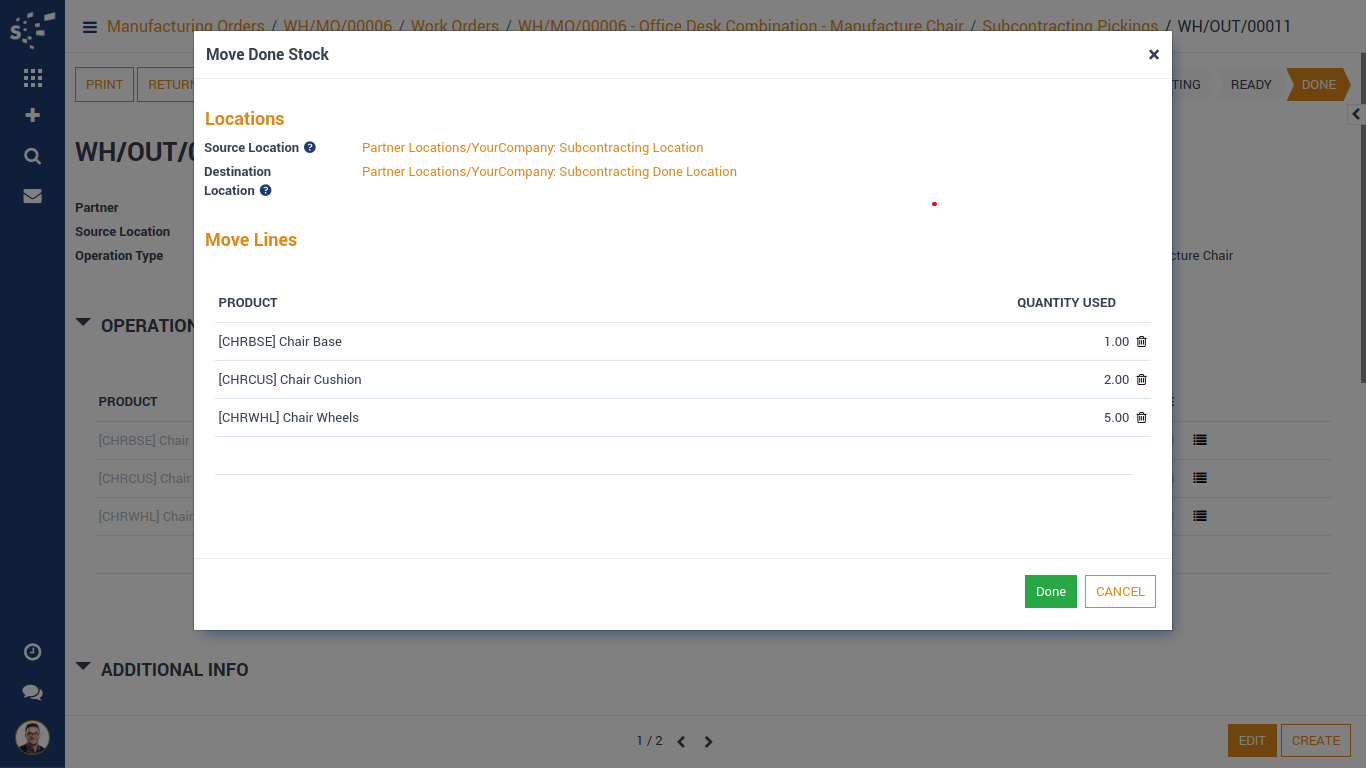

When user will click on 'Move Subcontract Stock' button, A pop-up will be visible showing raw material used in production process with available quantity in subcontract location. user will update quantity used in production process and move them to subcontract done location.

'Move Subcontract Stock' button will be visible in outgoing pickings only.

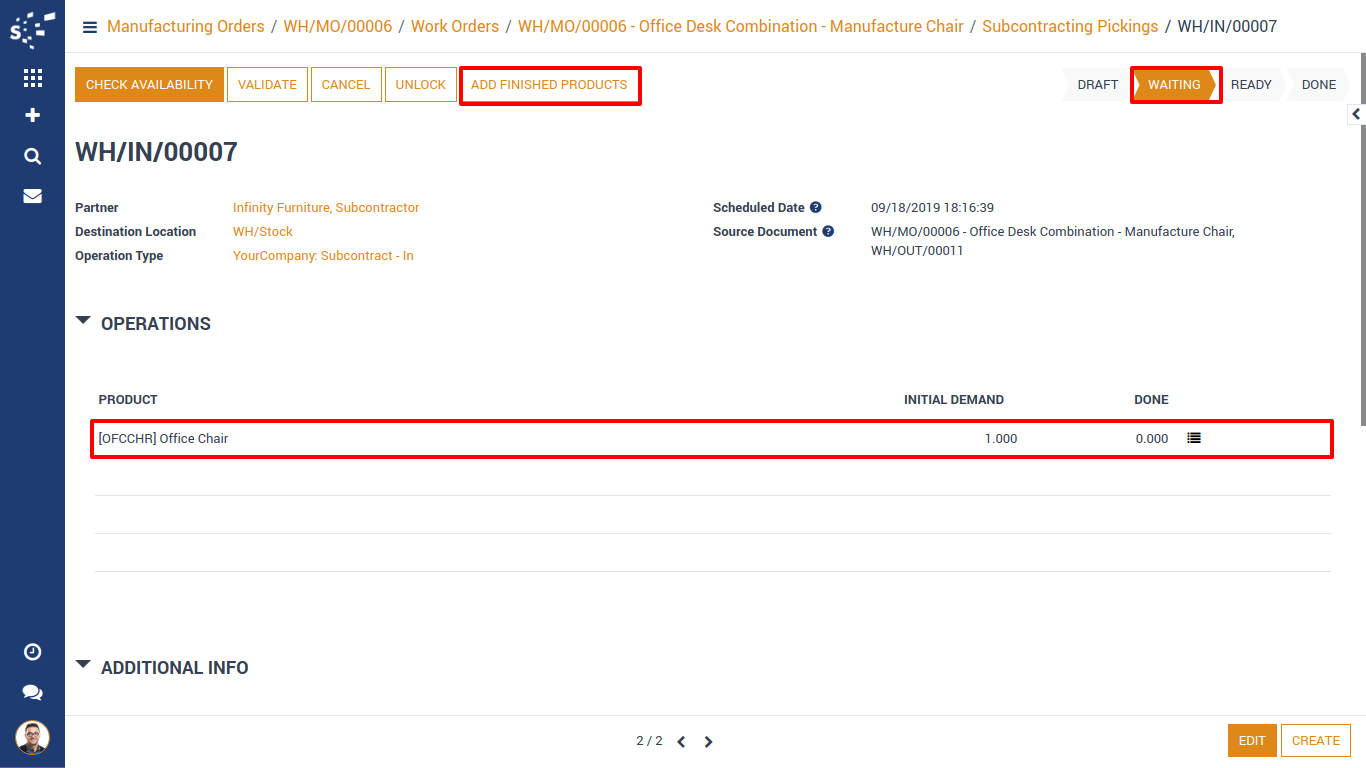

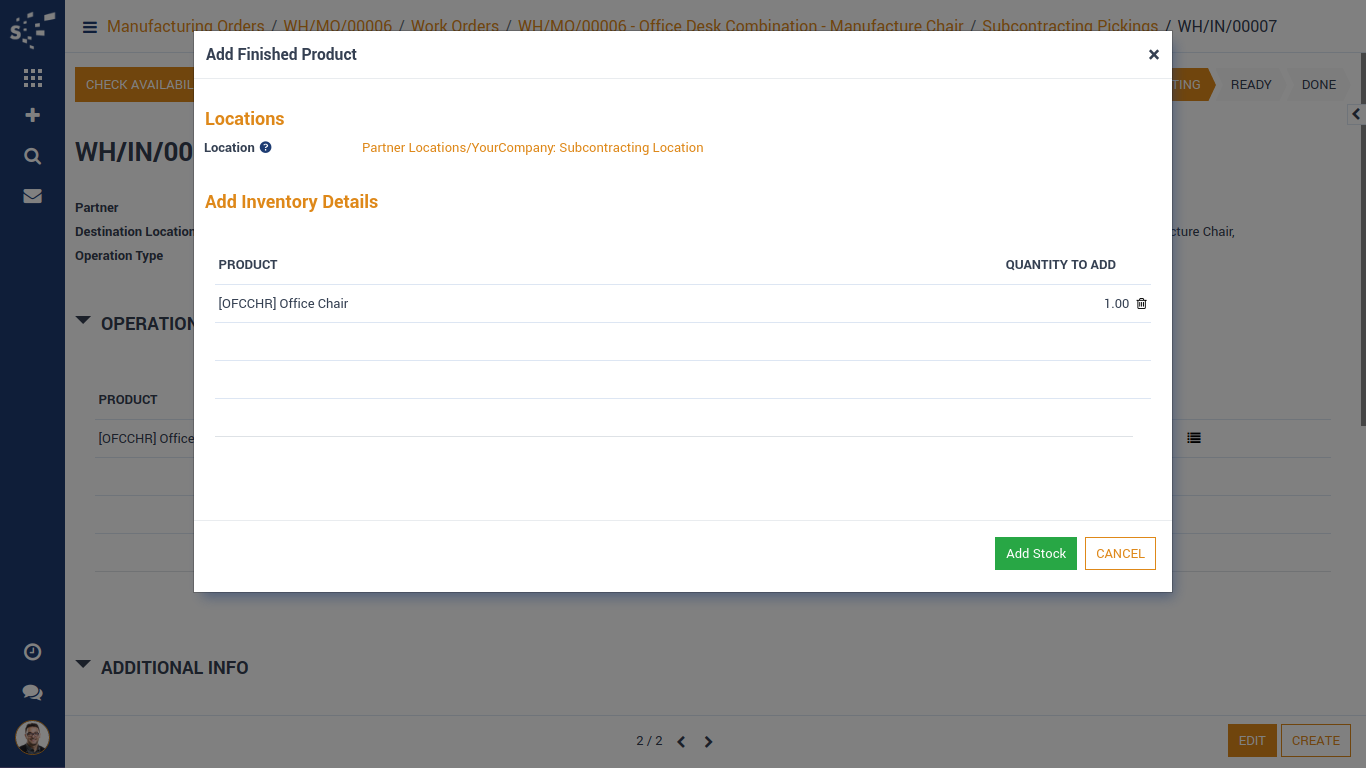

When Incoming picking is in 'Waiting' State, 'Add Finished Products' button will be visible. This process will be done once subcontract production is done and subcontract product is available at subcontract location.

When user will click on 'Add Finished Products' button, a pop-up window will be visible showing subcontracting product and quantity. User can update quantity if needed.

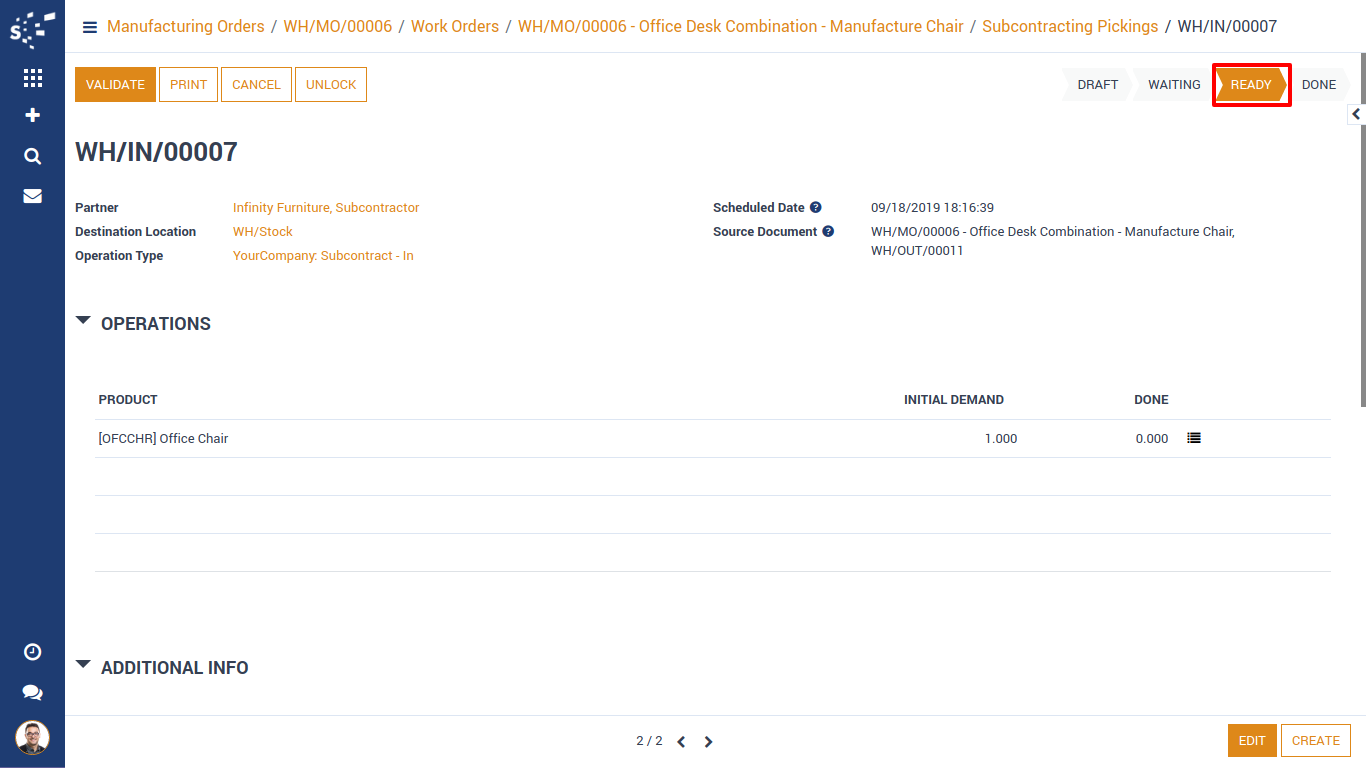

When user will add stock of subcontracting product, picking will move to 'Ready' state from 'Waiting' state.

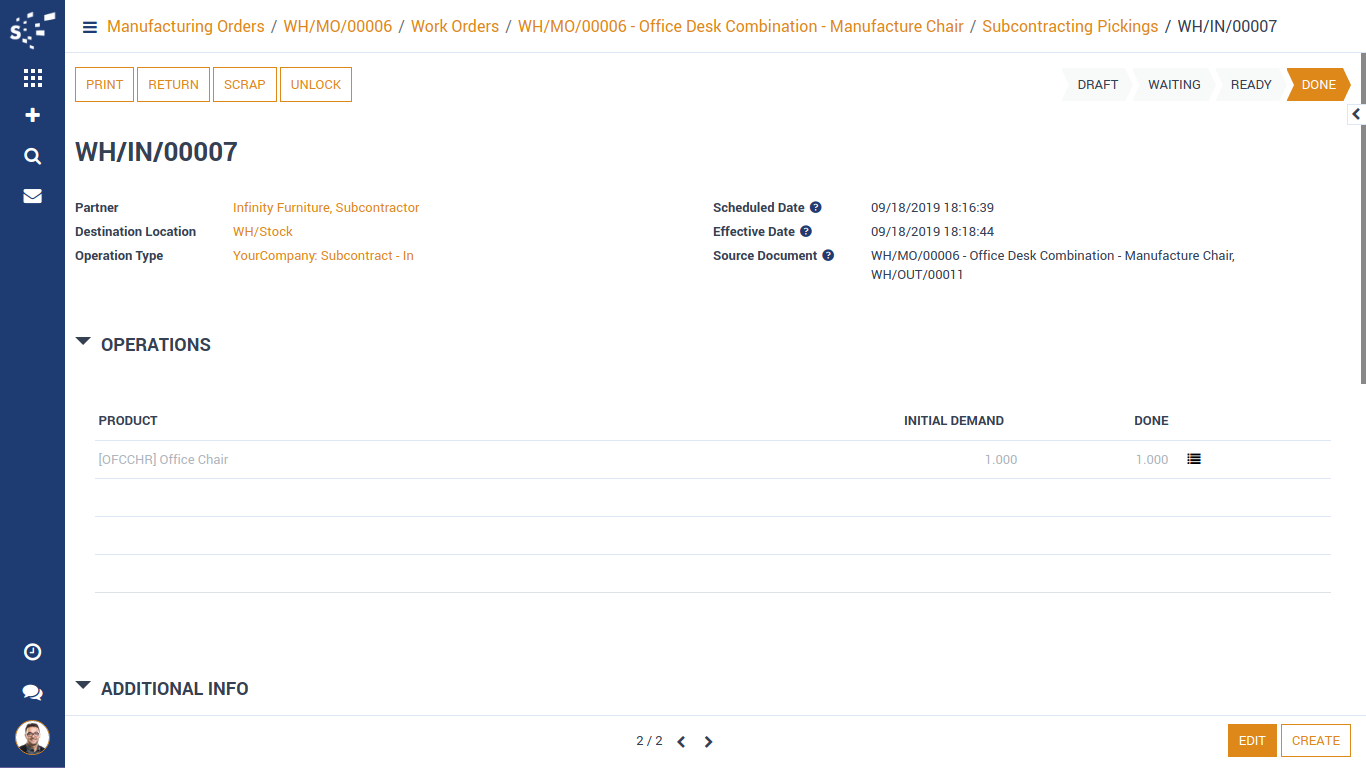

When picking is in 'Ready' state, user can transfer it to 'Done' state and subcontract product stock will be transferred to warehouse stock location.

Subcontract process creates a purchase order as well, for subcontracting service amount paid to subcontractor. User can update service amount if needed, confirm order and create bill.

A purchase bill will be generated from purchase order for payment of subcontracting services and invoice partner will be subcontractor.

Now, If user will go to manufacturing order and click on button 'Check Availability', Available stock will be reserved for subcontracting product.

Now, we can see warning is not in work-order anymore for raw material out of stock. we can process work order and finish process.

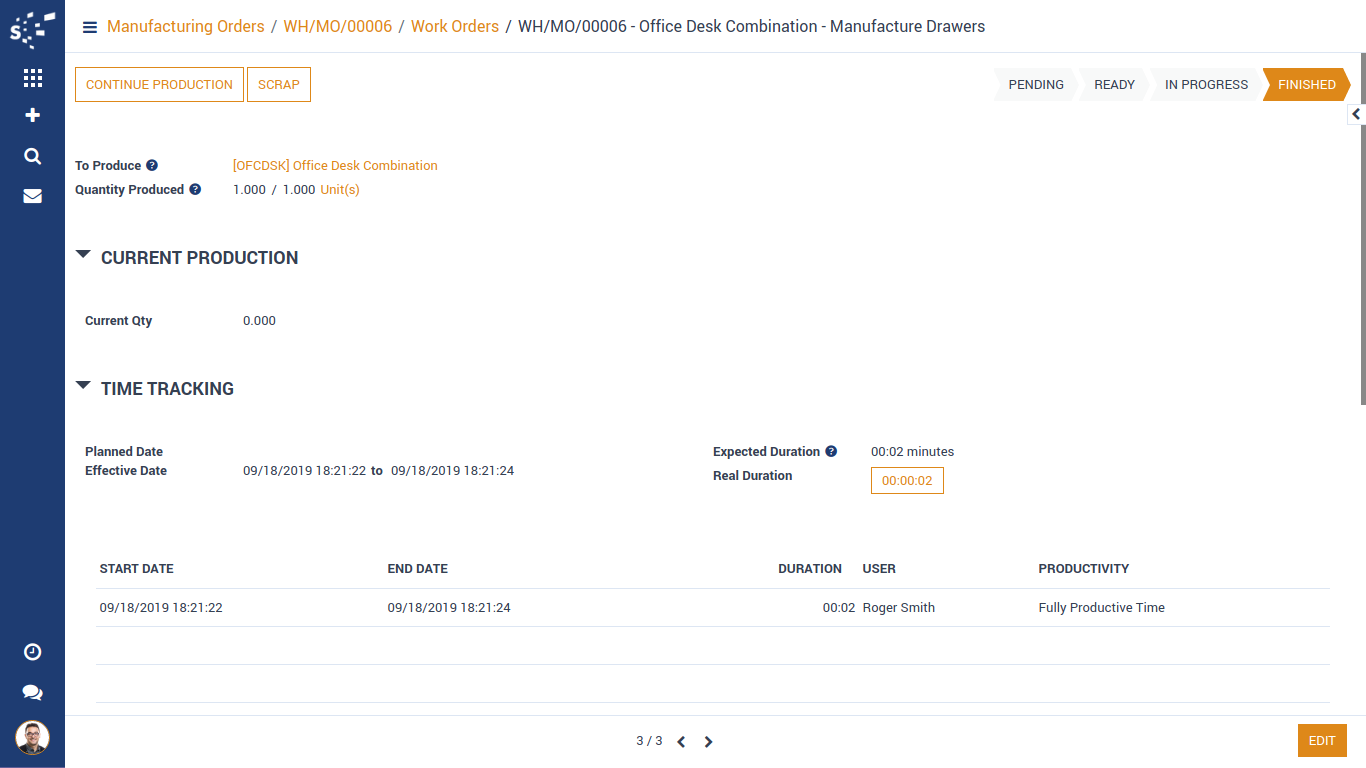

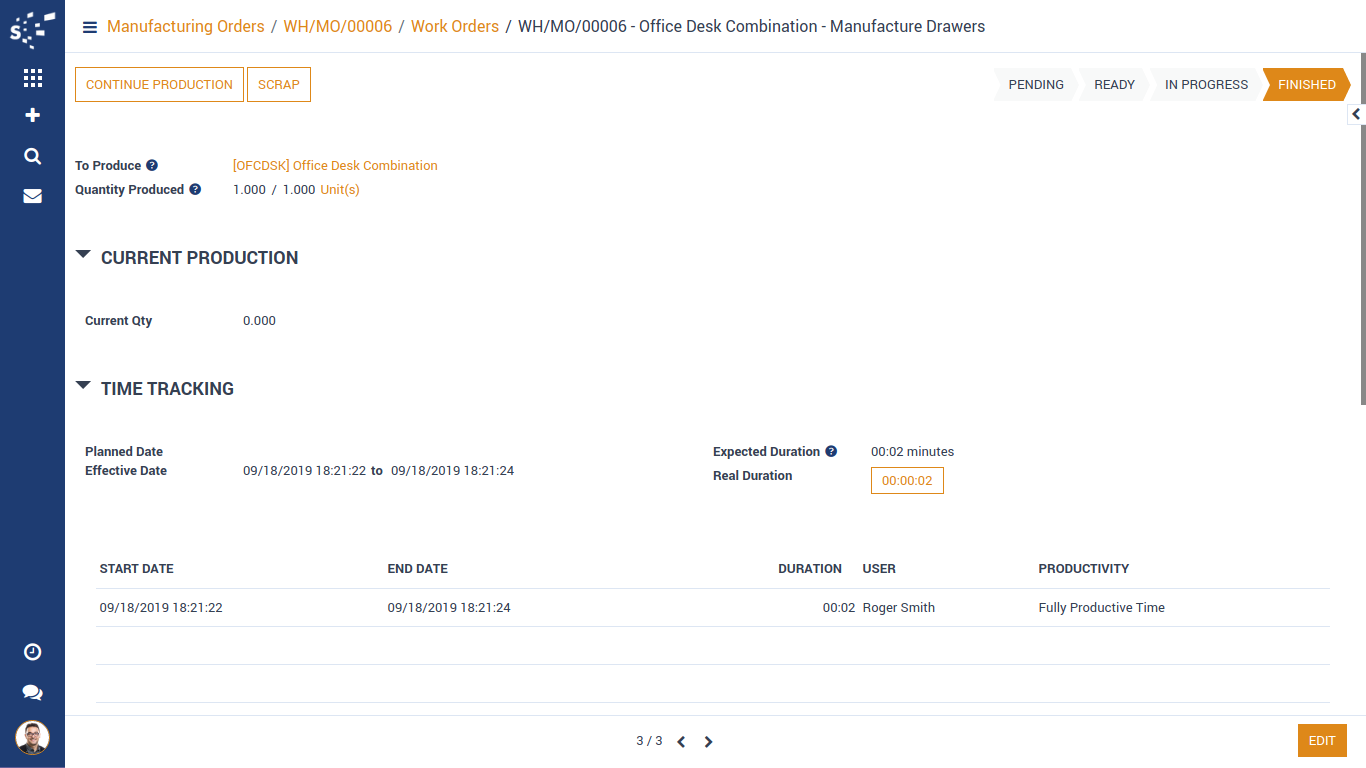

Third work-order is normal work-order. It's raw materials are available in stock so we can process is normally and finish process.

When all 3 work orders are processed successfully, we can finish manufacturing order and move it to 'Done' state.

Notes:

- All the apps are to be purchased separately, for individual versions and individual edition.

- One month free bug support period will be offered pertaining to any one server used, testing or live.

- Synconics is only responsible for providing the module zip file on your registered email, purchased from our app store or directly through our company.

- Synconics is not responsible for installation or updating of the module on any of your server.

- If an error appears in our app due to other custom modules installed in your system or if Odoo base source code is not updated on your system, to make it compatible with your source code, we'll charge you for our efforts to resolve those errors and make the module compatible with your source code.

- Please refer the document for configuration. If any support is needed for module configuration, installation, updating or any help is needed, it will be considered in paid support.

- Please note that you are not allowed to distribute or resell this module after purchase.

- This module is tested and working on Odoo vanilla with Ubuntu OS.

- Support services will be provided from Monday to Friday, 10:30 AM to 7:30 PM IST (Indian Standard Time).

- Support will not be provided during Indian public holidays or company holidays.

Once the user has seen at least one product this snippet will be visible.